Mumbai - 400004, India

ALLOY STEEL FORGED SOCKET WELD PIPE CAP

- Home

- SOCKET WELD PIPE CAP

ALLOY STEEL FORGED SOCKET WELD PIPE CAP

ASME B16.11 Alloy Steel Forged Socket Weld Pipe Cap, Global Supplier of ANSI B16.11 Alloy Steel Forged Socket Weld Cap, Forged Pipe Cap 3000LB Socket Weld, Socket Weld Forged Pipe Cap, BS3799 Alloy Steel Socketweld Forged Pipe Cap Wholesaler, Stockist of Alloy Steel Socket weld Pipe Cap, Forged Socket Weld Pipe Cap, Alloy Steel 310 Socket weld Pipe Cap Dealer in India.

Vishal Tube Industries is a manufacturer, distributor and supplier of Alloy Steel Socket Weld Caps. It is an innovative ISO certified company that uses responsive services to entice the customers. A Alloy Steel Socket Weld fitting is a kind of pipe fitting which is inserted into a recessed valve, fitting or flange. A Super Duplex Steel Socket Weld Cap is a type of pipe fitting, usually liquid or gas tight which covers the end of a pipe to stop the flow. The functions of a cap are similar to a plug. They have excellent corrosion resistance. They are mainly used for small pipe diameters. This vast variety is provided to the clients by the renowned stockist and exporter, Vishal Tube Industries, in multiple sizes, as per the customised requirements. They are offered to clients with the option of customising the size as per the individual purchasers.

We Manufacturer Our Products By High Grade Material To Provide Good Quality Socket Weld Caps To Our Domestic And Overseas Customers. Socket Weld Fitting accomplish a Lot of admiration by our clients owing to its high strength, dimensional correctness, high tension power, corrosion resistant and consistency products like Stainless Steel, Socket Weld Caps, Carbon Steel Socket Weld Caps, Alloy Steel Socket Weld Caps. These products are used in various commercial, industrial and automobile industries. We manufacture ANSI B16.11 Forged Socket Weld Caps using high grade of raw material by implementing most ultra modern technology. These products are clients can avail from us at various sizes, shapes and design as per the requirements.We are one of the top Manufacturers and Suppliers of ASME B16.11 Socket Weld Caps in Mumbai, India.

We are also manufactured these Socket Weld Cap in BS, DIN, JIS, SAE & IS Standards or any other international standards. They are also used to close the ends of hydraulic or pneumatic pipes and tubes. These Socket Weld Cap are available in different size, grades, specification & thickness as per the clients requirments.

Advantages

- Durable finish standards

- Accurate dimension

- Tensile strength

- Leak Proof

Specifications

| Schedule: | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Materials: | Alloy Steel ASTM SA 182 - E25, E26, E27, E28, E29B, E30B, E39B, E40B, E36B, E36C, E41B, AISI4130, AISI4140, AISI4340, 42CRMO4, 16MNCR5, 20MNCR5, 21CrMoV57, EN353, EN354, F11, F22, F91, F9, P11, P22, P91, P9, P5, P92, EN42J, EN8, EN19 |

| Type: | Socket Weld (SW) |

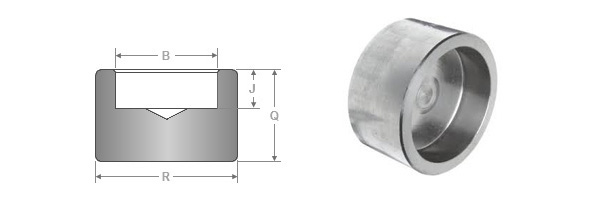

| Dimension: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

NPS 1/2 to 4 - 3000 LBS

| NPS | End to End | Outside Diameter | Minimum End Wall Thickness |

Minimum Length of Thread | |

| A | D | G | B | J | |

| 1/2 | 32 | 28 | 6.4 | 10.9 | 13.6 |

| 3/4 | 37 | 35. | 6.4 | 12.7 | 13.9 |

| 1 | 41 | 44 | 9.7 | 14.7 | 17.3 |

| 1¼ | 44 | 57 | 9.7 | 17 | 18 |

| 1½ | 44 | 64 | 11.2 | 17.8 | 18.4 |

| 2 | 48 | 76 | 12.7 | 19 | 19.2 |

| 2½ | 60 | 92 | 15.7 | 23.6 | 28.9 |

| 3 | 65 | 108 | 19 | 25.9 | 30.5 |

| 4 | 68 | 140 | 22.4 | 27.7 | 33 |

NPS 1/2 to 4 - 6000 LBS

| NPS | End to End | Outside Diameter | Minimum End Wall Thickness |

Minimum Length of Thread | |

| A | D | G | B | J | |

| 1/2 | 33 | 38 | 7.9 | 10.9 | 13.6 |

| 3/4 | 38 | 44 | 7.9 | 12.7 | 13.9 |

| 1 | 43 | 57 | 11.2 | 14.7 | 17.3 |

| 1¼ | 46 | 64 | 11.2 | 17 | 18 |

| 1½ | 48 | 76 | 12.7 | 17.8 | 18.4 |

| 2 | 51 | 92 | 15.7 | 19 | 19.2 |

| 2½ | 64 | 108 | 19 | 23.6 | 28.9 |

| 3 | 68 | 127 | 22.4 | 25.9 | 30.5 |

| 4 | 75 | 159 | 28.4 | 27.7 | 33 |

Uses & Application

| Chemical | Oil Mills | Petrochemical | Mining |

| Fertilizers | Shipbuilding | Power Plant | Steel Plant |

| Oil & Gas | Defence | Paper | Ports |

| Cement | Engineering Co. | Sugar | Government Org. etc. |

Packaging

Depending on the size of the diameter of the elbows these individually or in bundles are transported. Pipe fittings in bunches are taken together with metal strips or wires in the transverse direction. It is important to make sure that the strapping is very firm, so that the individual pipes can not move against each other and thereby suffer damage. Subject to transport, duration and turnover can be wrapped in eg plastic jute fabric and is provided at the bundle ends . specialty fittings shall be protected against corrosion and are usually coated or in appropriately chosen cases or wood-corrugated structures packaged. Specialty coatings, such as of PE, require padding to ensure that the protective layer is not damaged.

Marking of packages

Through a correct and complete marking of packaging will create the conditions to avoid misuse, accidents, wrong delivery, mass and volume losses and customs penalties. We do marking very clear and precise on Fittings. You should contrast clearly with the package, usually it is applied in black color

Types of Packaging

- Bundles (hexagonal)

- Wooden Boxes

- Crates (steel/wooden)

- Special crates for U-Bend tubes with each radius separated